TempView Thermal Imaging System

TempView Thermal Imaging System is a reliable way to ensure the success of your heated processes.

TempView Thermal Imaging System is an optional thermal imaging system that monitors the temperature of various devices/components to ensure uniform flow of fluid during the process.

TempView Thermal Imaging System ensures the success of heated dispensing processes like Underfill, Encapsulations, Dam and Fill, and more. The TempView Thermal Imaging System monitors the temperature of the entire substrate for complete heat profile characterization. You can select regions of the product to be monitored during the heating process. Now you can accurately monitor the temperature of specific devices to be sure they are up to temperature before starting a process.

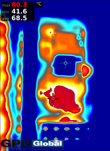

TempView Thermal Imaging System captures and displays subtle thermal patterns and small temperature differences (Image 1) with a high sensitivity detector. The undiluted thermal image shows hidden heat patterns that point out hot spots, energy waste, cool areas, etc. This allows you to instantly recognize where a problematic heat pattern is located. Now you can regulate heat to various devices/components as needed and be confident that devices are reaching the programmed temperature before a process starts. In addition, the gantry can wait in a cool area during the temperature monitoring process to prevent overheating of the pump and Z-axis.

Unlike the Single Point monitoring system, the TempView Thermal Imaging System provides a full and complete thermal image of the substrate. TempView Thermal Imaging System monitors temperature in various zones of the substrates, ensuring the areas to be processed are at set temperature. Process results are enhanced with the zones to be processed at the correct temperature.

TempView Thermal Imaging System mounts above the work area of a dispensing system for a complete view of the work area (Image 2), with the primary focus on the substrate. The imaging system software programs are designed to allow you to highlight regions of the substrate as needed; the system is notified when the substrate reaches the programmed temperature.