Conductive Adhesive & Non-Conductive Adhesive

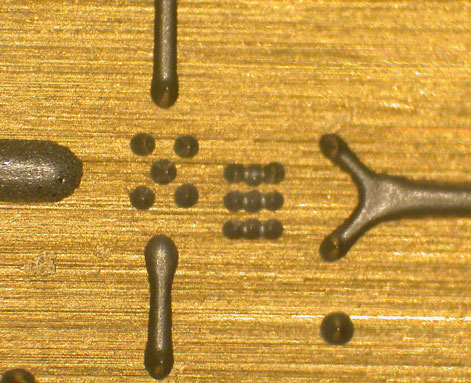

Conductive Adhesive is an electrically conductive material that adheres dies and other small components to substrates; typically ceramic, gold, and FR4 substrates. It makes the electrical and adhesive connection between device and electrical pad and substrate. For the most part, conductive adhesives are not reworkable like a solder paste connection. Non-Conductive Adhesive is used for holding a device to a substrate without an electrical connection or can be used as an insulator between pads. When using our fully automated dispense platforms, virtually any dispense pattern can be programmed to meet your process requirements. Conductive inks are another example of conductive fluids that can be used for drawing electrical traces on a substrate. Example: Bus Bar Conductive Fluids.

Conductive and non-conductive adhesives are typically presented to system as pre-mixed and frozen in 3 to 10 cc syringes. For most consistent dispense results, we recommend using syringes filled with fluid that can be used within pot life. Using fluid beyond pot life can result in variable dispense results.

Conductive Adhesive & Non-Conductive Adhesive Dispensing

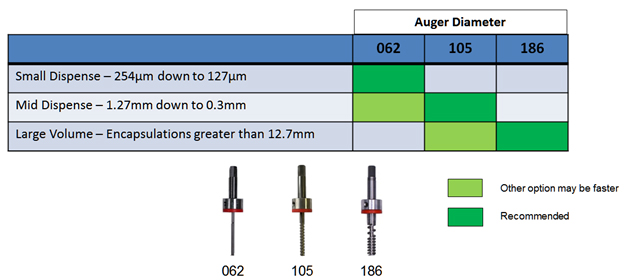

When dispensing conductive and non-conductive adhesives, we recommend using either our Precision Auger Pump or our Jet Pump, depending on application. Jet dispensing can be used when deposit size needs to be a dot diameter or line width down to 0.4 mm. Jet dispensing is also recommended if substrate is not particularly flat. Our most highly recommended pump, Precision Auger Pump, dispenses the smallest quantities (micro volume) of fluid down to a dot diameter of 150 µm. Precision Auger Pump handles a wide range of dispense volumes and rates with a simple swap of auger/cartridge assembly. For low viscosity conductive inks, PCD Volumetric Pump is a recommended solution.

As with any fluid, conductive and non-conducive adhesives have dispense characteristics that can be affected by nozzle selection. Our standard Precision Dispense tips for Precision Auger pump are available in sizes down to 100 µm. For improved wetting, our Precision Dispense Tips are available in either steel or ceramic.

Couple our Precision Auger Pump with Real Time Process Control System (FPC) for improved dispensing results over full range of syringe fluid level. Real Time Process Control ensures a constant supply of fluid to the pump regardless of reservoir size or fluid level. FPC monitors pressure of fluid entering dispense pump and makes adjustments to reservoir feed pressure, resulting in a consistent feed to the pump.

GPD Global's fully automated dispense systems - MAX and DS Series - have features necessary for a successful dispense process such as fiducial alignment, surface sensing on multiple levels, and the ability to program complex patterns that may be recalled as needed. Compatibility with our full range of dispense pumps and the ability to use up to three pumps in a single process make our systems exceptionally versatile.

Additionally, we offer a retrofit kit for retrofitting either Precision Auger Pump, PCD Volumetric Pump, or NCM5000 Jetting Pump into your platform. Retrofit kits come complete with a controller and the necessary interface cables and mounting.

Recommended Adhesive Dispensing Videos

- Dispense Epotek H20E-PFC-D with Precision Auger 062

- Dispensing Ablestik 84-1LMI with NCM5000 Jetting Pump

- Dispensing dots and X with Precision Auger Pump

- Dispensing Silver Ink Dots with PCD Volumetric Pump