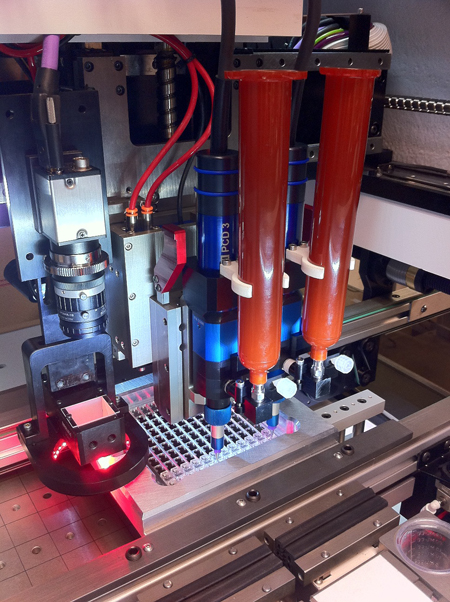

High Precision Dispensers

MAX Series High Precision Dispensers Available for Heated & Non-Heated Applications

The MAX Series is the premier line of GPD Global high precision dispensers. This dispense equipment can process a wide variety of dispense applications:

- MicroVolume Solder Paste and Conductive Adhesive

- Underfill

- Surface Mount Adhesive

- Dam and Fill

- Encapsulations

- LED Encapsulation

- Masks

- and more

At the heart of all MAX Series systems is a solid unibody with molded frame. It yields outstanding stability and unparalleled accuracy. Other standard features include:

- Automatic Vision

- Fully Automatic XYZ Backlit Calibration Station

- Needle Cleaning

- Contact Surface Sensing

- Toolless Taper-Lock™ Pump Mounting Hardware

Each MAX Series system has an XY positional capability of ±25 µm (±0.001") and Z axis repeatability of 7 µm (0.0003"). Use a MAX Series dispense system to expand your process capability to new horizons. Process development is easy with a system configured with the Process View Camera. The camera enables the operator to view the dispense process on an external monitor.

A work area of 358 mm x 305 mm (14.1" x 12") is available when a system uses a single pump. To handle a variety of applications and complex processes, configure a MAX Series system with up to two different dispense pumps. The system automatically changes between pumps during a process run. The addition of a second dispense station reduces the system work area to 305 mm x 305 mm (12" x 12"). All components of the system - the camera, both dispense stations, and the surface sensor - can reach the full extent of this work area

To increase throughput, configure your system as a tandem pumps system. Two pumps of the same type will dispense on the product in tandem.

Models

Select the MAX Series model that meets your production requirements: