Hot Melt Dispensing

PUR hot melt dispensing is widely used in product assembly operations such as mobile device electronics assembly.

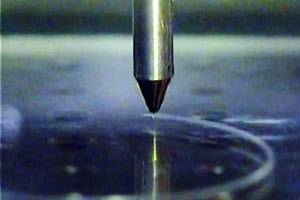

You can get hot melts dispensed down to 120 µm line width with our Precision Auger pump when it's equipped with its smallest auger cartridge configuration of 062 and a 50 µm S-type dispense tip.

PUR (Polyurethane reactive) Hot Melt dispensing is typically applied from a heated syringe at 100-120° C. PUR hot melts form a strong bond that continues to strengthen as the materials react with moisture in the air. Polyurethane hot melts create strong chemical bonds that withdstand extreme conditions. This makes PUR hot melts an excellent choice for a permanent bond.

Masking materials can also be formulated as a hot melt. Hot melt is an excellent choice because it solidifies rapidly when fluid temperature decreases to ambient, thus eliminating the extra steps of air cure, UV cure, and oven heat cure typically required before the reflow process.

Our fully automated dispense systems have the features necessary for a successful dispense process such as fiducial alignment, surface sensing on multiple levels, and the ability to program complex patterns that may be recalled as needed.

120 µm Line Width Hot Melt Dispensing

Dispensing Hot Melt with Auger Pump

Hot Melts are best dispensed with a Precision Auger pump configured with a body heater and syringe heater that heats up to 130° C. The auger cartridge assembly has a copper core for quick and uniform heat transfer.

The Precision Auger Pump can be retrofitted into your dispense system with a Servo Pump Controller. The controller not only controls all aspects of pump motion, but also controls two heated areas, namely the pump body and syringe heater. This configuration makes for a complete package. Also available: our tool-less taper-lock mounting hardware. It provides secure and stable mounting, plus quick release with the push of a lever.

75 mm/sec Hot Melt Dispensing

Dispensing Hot Melt with Jetting Pump

Our NCM5000HM Jetting pump is specifically designed for high temperature operations. It is capable of dispensing hot melts at 75 mm/sec. The NCM5000HM Jetting pump is a high-performance system that is easy to use and especially EASY TO CLEAN!

Some unique features for using a Jetting Pump for Hot Melts dispensing include:

- Diaphragm Technology

- Only the nozzle and diaphragm are in contact with the fluid

- Disposable feed tube

- Uniform heat distribution

We offer a retrofit kit for retrofitting NCM5000 Hot Melt Jetting Pump into your platform. Retrofit kits come complete with a controller and the necessary interface cables and mounting.